-

Керамические шарикоподшипники

-

608 керамических подшипников

-

Гибридные керамические подшипники

-

Керамические подшипники ролика

-

Керамический толкнутый подшипник

-

Керамический сползая подшипник

-

Предварительная структурная керамика

-

Шарик нитрида кремния

-

Шарик кремниевого карбида

-

Шарик Zirconia керамический

-

Шарикоподшипники кремниевого карбида

-

Шарикоподшипник нитрида кремния

-

Подшипник Zirconia керамический

-

Механическое запечатывание

-

Подшипник кремниевого карбида

-

РобертаИх керамические подшипники высокой точности, хорошие качественное и недорогой. Мы имеем сотрудничество в течение многих лет.

РобертаИх керамические подшипники высокой точности, хорошие качественное и недорогой. Мы имеем сотрудничество в течение многих лет. -

Ольга WeinbergЭта компания наши надежные и профессиональный поставщик керамических подшипников в течение многих лет, их керамические подшипники, которые использованы в нашем насосе хорош в качестве.

Ольга WeinbergЭта компания наши надежные и профессиональный поставщик керамических подшипников в течение многих лет, их керамические подшипники, которые использованы в нашем насосе хорош в качестве.

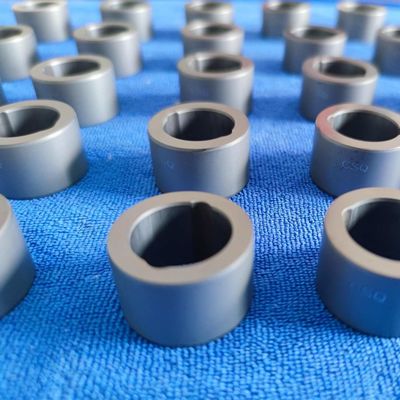

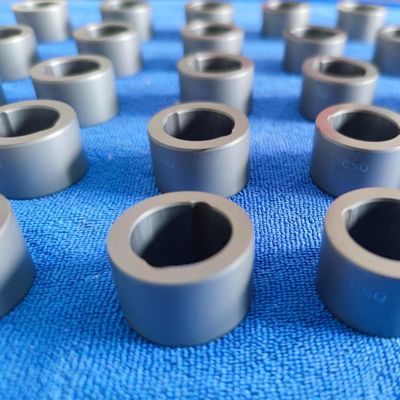

Advanced Ceramic Sleeve For Industrial Applications High Temperature Tolerance And Corrosion Resistance

| Место происхождения | Китай |

|---|---|

| Фирменное наименование | CSQ |

| Сертификация | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Номер модели | индивидуальные продукты |

| Количество мин заказа | 20-50 ПК |

| Цена | negotiable |

| Упаковывая детали | Пенопласт+картонная коробка |

| Время доставки | 20-45 дней работы |

| Условия оплаты | T/T |

| Поставка способности | 2000 штук в месяц |

Свяжитесь я бесплатно образцы и талоны.

WhatsApp:0086 18588475571

Вичат: 0086 18588475571

Скайп: sales10@aixton.com

Если вы имеете любую заботу, то мы предусматриваем 24-часовую интерактивную справку.

x| Имя | Подгонянный керамический сползая подшипник рукава | Категория | Керамические подшипники для скольжения |

|---|---|---|---|

| Материал | Силиконовый карбид | Размер | Подгонянный, согласно чертежам |

| Применение | Насосы | Пакет | Пенопласт+картонная коробка |

| Качество | Высокая точность, длительный срок службы, OEM серийный | Спецификация | Стандартный размер и индивидуальные |

| Attribute | Value |

|---|---|

| Name | Customized ceramic sliding sleeve bearing |

| Category | Ceramic sliding bearing |

| Material | Silicon carbide |

| Size | Customized, according to drawings |

| Application | Pumps |

| Package | Foam + carton box |

| Quality | High precision, Long life, OEM service |

| Specification | Standard size and customized |

Custom-engineered silicon carbide (SiC) sliding bearing sleeves represent a cutting-edge solution for demanding industrial, automotive, and aerospace applications. These precision components deliver superior performance compared to conventional steel bearings.

- Exceptional Corrosion Resistance: Silicon carbide's inherent stability ensures outstanding resistance to corrosive chemicals and harsh environments.

- Reduced Friction & Wear: The ultra-smooth, high-hardness surface minimizes friction and wear, enhancing operational efficiency.

- High-Temperature Durability: Maintains structural integrity in extreme heat, perfect for high-temperature applications.

- Max Temperature up to 1650℃

- Low density: 3.15-3.18 g/cm³

- High strength and hardness (2800 HV5)

- Low thermal expansion: 4.0 (10-6/℃)

- High thermal conductivity: 120 W/m°K

- High elastic modulus: 410GPa

- Superior chemical stability, resistance to acid and alkali corrosion

- Higher temperature resistance (up to 1650℃)

- Superior performance in thermal cycling

- Enhanced anti-seizure & anti-jamming properties

- Oil-free operation capability

- Exceptional corrosion resistance

- Electrical insulation & anti-static properties

- Non-magnetic & contamination-resistant

With three factories in China and advanced pressing, sintering, and processing machines, we specialize in customized ceramic bearing solutions. Our company possesses eleven invention patents and has been manufacturing ceramic bearings since 1982.

- Free sample bearings available

- ISO standard compliant production

- In stock bearings for quick delivery

- Small order quantities accepted

- OEM bearing service

- Customized bearing solutions

- Competitive factory pricing

We are a factory in Beijing, China with over 40 years of experience producing ceramic bearings, serving domestic and international clients.

We produce samples before mass production, conduct precise inspections, and use double packaging (foam + carton) to ensure product quality.

As an integrated company with three factories and modern equipment, we offer better delivery times, product quality, and customized solutions.

We cooperate with raw material suppliers to ensure stable quality and pricing. Our customer-focused approach delivers quality products and after-sales service. Contact us to discuss your requirements.